When states implement new marijuana programs, and license applications begin to be filled out, there is usually a scramble for real estate in densely populated metropolitan areas. Hopeful cultivators may even try to outbid one another to get the largest warehouses in the best neighborhoods.

But not Tim McGraw, founder of Illinois medical cannabis producer Revolution Enterprises.

Instead of trying to join the bidding wars in larger cities when Illinois legalized medical cannabis in January 2013, McGraw started making cold calls to rural towns in need of an economic stimulus.

“A lot of cannabis companies,” McGraw says, “find a location, and then try to convince, so to speak, the community to accept them and get the support. We did the opposite: We worked backwards into the location, by finding communities that wanted us.”

That seemingly counter-intuitive approach paid off for Revolution Enterprises. It was awarded two of the state’s 19 cultivation licenses: one for a facility in Barry, and another dedicated to the company’s flagship facility in Delavan.

“[Being in smaller communities], was, I think, a huge differentiator between us and the other applicants,” McGraw says.

Now, at the tail end of 2016, those licenses have turned into two 75,000-square-foot facilities and Revolution Enterprises is eyeing new markets in which to expand. McGraw, however, is still focused on making sure the small towns aren’t left in the dust of his big plans.

Being Part of the Community

On the night of July 16, an EF2 tornado touched down in Delavan. Wind gusts of 120 mph leveled 51 homes on a 1.3-mile-long path of destruction, leaving one Delavanite seriously injured.

Revolution Enterprises’ facility in the town was still under construction when the tornado hit, but no damage was done to the structure. So what McGraw did next came as a surprise to the entire town.

“I talked to the mayor at 5:00 in the morning, a few hours after the tornado hit, and just said, ‘What can we do to help? Do you need help with cleanup? Do you need bodies? What do you need?’” McGraw says. “And she said, ‘You know, Tim, we just need places for people to stay.’”

So that’s what Revolution Enterprises provided by footing the hotel bills for those families who saw their homes destroyed. McGraw also bought storm detectors for any household in town that wanted one. That way, he explains, Delavan’s residents could have more time to prepare their homes if another tornado approached the town.

His reasoning behind those decisions is simple. “I saw the devastation in this small town … so that’s just being a good neighbor, you know?”

McGraw made a point to set up shop in smaller communities rather than in larger, urban areas. Not only is Revolution Enterprises making a bigger impact in the community, but areas in need of economic development often will be willing to work with businesses, more so than cities like Chicago, McGraw says.

“Before construction, the towns were [ghost towns],” McGraw explains. “There’s maybe one person for lunch at the local restaurant, where now there’s 60-plus employees down the street, filling up the restaurants for lunch, and then going out for a drink after work.”

And the towns have shown their appreciation in return.

When McGraw tried to winterize his Barry site while it was still under construction, his crew was struggling to place a tarp over the construction site with 40 mph winds blowing it away at every try. Locals volunteered their time and supplies to help, laying down bails of hay and old tires to keep the tarp from flying off.

“That stuff doesn’t happen in the city,” McGraw says. “You don’t get the locals reaching out and saying, ‘Oh, how can we help?’”

McGraw also credits the support Revolution Enterprises has received from these small communities as the reason the group became operational so quickly after receiving its licenses.

“Not only did it help with the applications, but it helped us in meeting the requirement of being operational within six months. We built two 75,000 square feet of the most advanced cannabis facilities in the world, and we did it in four and a half months,” he says.

Advancing the Science

And advanced his facilities are, although you wouldn’t think so when you look at them from the outside.

A 12-foot-high barbed-wired fence surrounds an otherwise plain, green and beige sheet-metal building. How to cross that fence is just the first feature of Revolution Enterprises’ facilities.

“To get in …, you need to check in,” explains Eric Diekhoff, general manager for Revolution Enterprises – Delavan, where he oversees day-to-day operations. “If you’re an employee, you have a card that you scan, and it has a personalized PIN you need to enter to get into the gate.”

If you’re a visitor, you need to speak to and check in with the facility’s on-duty security guard in a “man-trap” room before being escorted to whom you need to meet.

These security measures and features are all put into place to secure the approximately $17 million investment the company put into each of the facilities. Delavan is especially valuable to McGraw’s group as it houses all of Revolution Enterprises’ research and development labs, in-house testing rooms, and extraction labs, where it creates everything from CO2 oil to live resin, shatter, sap and moonrocks, among other products.

Research and development plays a large role in Revolution Enterprises’ business plans. The laboratories resemble more of what you might find in a pharmaceutical setting rather than a typical cultivation business. Lab technicians and researchers experiment with phenotypes to discover which cultivars produce the highest yield in the facilities’ conditions, new extraction products are developed and tested, and growers breed new cultivars to address different patient needs.

“The whole purpose of building these facilities to the specs that we did was to build laboratories that are dedicated to advancing the science of cannabis,” McGraw explains. “We’re not just here to pump out flower and make money.”

Despite his background in real estate development (both commercial and industrial), the learning curve in designing the facilities was still steep for McGraw. He says that is primarily because most engineers have not built cannabis facilities like these before.

“Every room within the facility is its own unique environment – the CO2 levels, the humidity, the temperature, all of that – depending on what strain or what you’re doing in each one of those rooms, or whether it’s flower, or veg, or whether you’re growing a sativa or an indica,” he explains.

Using environmental controls by Automated Logic, McGraw can control the HVAC for every room in either of his facilities directly from his phone. (“Not that I would touch it, because I’d mess it up,” he laughs.)

That system also helps avoid spikes in the rooms’ environments, says Revolution Enterprises COO Dustin Shroyer. It does so by enabling controllers to program levels “to the second instead of down to a 15-minute increment or waiting for a spike for our [HVAC] to kick on. We really don’t have spikes in cooling or heating or humidity.”

‘Boutique Quality on a Mass Scale’

Despite its high-tech research and development, Revolution Enterprises’ approach to plant cultivation is much more basic.

“We try to keep it really simple,” Shroyer says. “Cultivating plants is based off evolutionary science and how plants were meant to grow. … We just try to pick up where nature left off.”

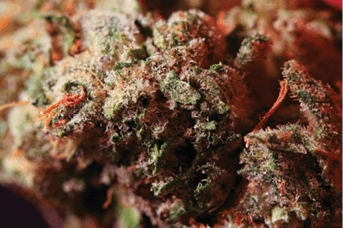

That means that instead of using hydroponic growing methods, which offer more control over every parameter of growth, Revolution Enterprises grows in a carbon-rich semi-soil using humus. Shroyer says this medium is light and dries out often, meaning it won’t get bogged down and promotes rapid root formation. Add some microbial life to the mix, and, he says, you have a recipe for high-quality cannabis.

“We believe that we achieve the highest quality and most robust benefits when it’s grown the way it was meant to be grown, the way it’s been grown for millions of years,” Shroyer says.

Picking up where nature left off also means that while environmental controls are fully automated, crops are hand-watered and hand-fertilized. According to both Shroyer and McGraw, hand-watering and hand-fertilizing gives their growers a chance to learn the different traits of each of their cultivars; when growers start to rely too much on automation systems and not enough on physical contact, mistakes can happen.

“When you take out those opportunities for inspection, you might leave a hermaphrodite flower go a little bit too long and result in more seedage in your crop,” Shroyer says. “So many people are turning to commercial cultivation and treating every strain the same, a blanket coverage throughout an entire facility, and what that results in is just really spotty quality.”

Growers having direct contact with their crops daily also brings a home-grown feel to Revolution Enterprises’ products. “We’re trying to produce a boutique quality on a mass scale,” Shroyer says.

This increased contact can sometimes bring extra risks of contamination, especially in Illinois, where all pesticides and fungicides are strictly prohibited during the crop’s flowering stage.

McGraw and Shroyer, however, have established rigorous processes to ensure that no outside contaminants ever reach their crops. For example, workers who are scheduled to be working in a flowering room need to walk through six key-card-secured doors from the moment they get into the facility to when they start working with their plants, according to Shroyer. These include locked changing rooms where employees may shower if needed and put on their work scrubs.

The company also installed UV lighting in its HVAC systems. As air passes through the system, mold spores that aren’t filtered out by high-micron filters get eliminated by UV light, Shroyer says. This mitigates the risk of contamination from powdery mildew and other crop-decimating fungi.

Controlled Burn

After being signed into law in January 2013 by then Governor Pat Quinn, Illinois’ Medical Cannabis Pilot Program has been overseen by current Governor Bruce Rauner, who has fought petitions from patients looking to add qualifying conditions to the state’s pilot program.

(The state of Illinois has been and is currently being sued by a group of eight citizens over qualifying conditions. The most recent court decision resulted in PTSD being added to the list of qualifying conditions under the pilot program through Senate Bill 10 (SB 10). Also, the state was ordered on Sept. 21, 2016, to add chronic post-operative pain to its medical cannabis program.)

“We’re not just here to pump out flower and make money.” — Tim McGraw, founder, Revolution Enterprises

As a result, the state’s medical cannabis market is much smaller than what was initially projected. Illinois had just 12,000 registered qualifying patients as of Nov. 2, despite being the fifth most populous U.S. state. For comparison, Arizona’s program was serving 89,405 patients as of March 1, despite only being the country’s 15th most populous state.

This slow start has forced Revolution Enterprises to slow down production to keep costs down as it waits for the market to mature. It is currently running between 10 percent and 12 percent of its canopy capacity, according to Shroyer.

“We’re growing eight strains in a 45-light room because that’s where our market is right now as far as production per strain,” Shroyer explains.

“Every market starts off and grows slowly,” he continues.

To add to the pressures, McGraw says competitors within the state have been undercutting the market’s prices to gain market share. For a company like his that doesn’t want to skimp on the quality of its products, this meant coming up with creative ways to compete.

“We just don’t sell B-grade. We sell popcorn,” McGraw says. What he is referring to as “popcorn” is A-grade cannabis with a less-than-pristine presentation. That way, he says, patients can still get the high-quality product they expect from his brand at a more competitive price.

While McGraw admits his group has “quite a bit of ramp-up yet to do operationally,” these measures, coupled with being able to manage and adjust the company’s budget as the market shifts, are what have allowed Revolution Enterprises to remain the state’s biggest player through what Shroyer calls “burn years.”

“No program is going to start with 100,000 patients who didn’t have home grows for the past five years. … Every program takes five years to build,” Shroyer says. “That’s the No. 1 mistake made by any startup company: not budgeting appropriately for how many years of burn you’re going to have while you’re operating and building your brand.”

But McGraw isn’t worried about his brand and is looking into expanding into other states in the near future. He believes that, “within the next 24 months … we’ll have either [roll-up mergers] or licensing in a few more states.”

But what truly matters for McGraw is that Revolution Enterprises continues to lead the way when it comes to quality and cannabis science.

“We plan to set the standard, and continue to raise the bar.”